Oil Free Compressor

HIGH QUALITY HIGH PRECISE MANUFACTURER & SUPPLIER

Leading the Way in Oil-Free Compressor Innovation and Quality

Established over a decade ago, our company has emerged as a leading manufacturer and supplier of oil-free compressors, leveraging cutting-edge technology and engineering expertise. With a state-of-the-art production facility and a dedicated workforce, we have consistently delivered high-quality products that meet the diverse needs of various industries. Our commitment to innovation and excellence has enabled us to expand our market reach globally, establishing a robust presence in sectors such as pharmaceuticals, food processing, and electronics.

Our oil-free compressors are designed to deliver clean, reliable air without the risk of oil contamination. Utilizing advanced materials and innovative engineering techniques, these compressors offer numerous advantages, including enhanced efficiency, lower maintenance requirements, and significant energy savings. Their compact design allows for flexible installation, making them ideal for applications where space is a concern. Industries rely on our compressors for critical processes such as packaging, pneumatic tools, and medical equipment, where air purity is paramount.

We pride ourselves on our expertise and influence in the oil-free compressor market. Our products are recognized for their durability and performance, backed by rigorous quality control measures and certifications. We understand the importance of customer satisfaction, which is why our service philosophy emphasizes proactive support and comprehensive after-sales assistance. Our dedicated technical team is always on hand to provide guidance, ensuring that our customers maximize the benefits of our products.

At our company, we believe in continuous innovation. We invest in research and development to enhance our product offerings and stay ahead of industry trends. By prioritizing sustainability and efficiency, we aim to contribute positively to our customers’ success and the environment. Choose us for your oil-free compressor needs and experience unmatched quality and service.

what is a oil free compressor?

An oil-free compressor, also known as an oil-less compressor, is a type of air compressor that operates without the use of lubricating oil in the compression chamber. Traditional air compressors typically use oil for lubrication and cooling purposes within the compression chamber, but oil-free compressors eliminate the need for oil in their operation. Instead, they employ alternative methods to achieve lubrication and cooling, making them suitable for applications where oil contamination is a concern or where oil-free air is required.

Oil Free Compressor For Sale

-

CM/B industrial frequency oil-free screw air compressor

-

CM/G medium pressure industrial frequency oil-free screw air compressor

-

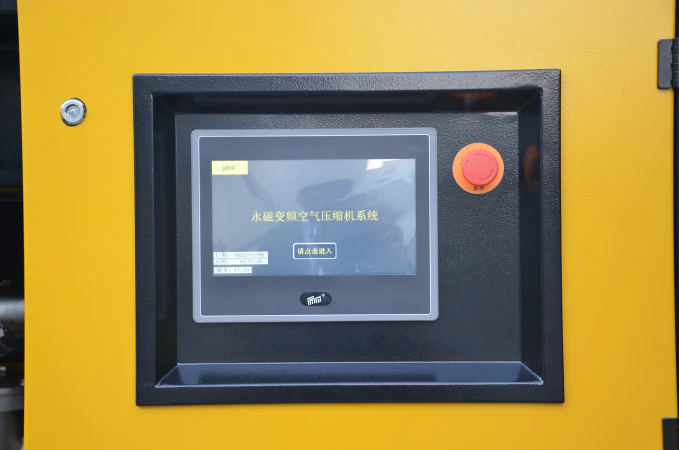

CM/GPV medium pressure permanent magnet variable frequency oil-free screw air compressor

-

CM/PV permanent magnet variable frequency oil-free screw air compressor

-

CM/PV permanent magnet variable frequency oil-free screw air compressor

-

CMW oil-free scroll air compressor

Oil-Free Compressor VS Micro oil air compressor

| Feature | Oil-Free Compressor | Micro Oil Air Compressor |

|---|---|---|

| Lubrication | No oil required; uses special materials for wear | Uses a small amount of oil for lubrication |

| Air Quality | Provides clean, oil-free air, ideal for sensitive applications | May produce oil carryover, not suitable for sensitive applications |

| Maintenance | Generally requires less maintenance; no oil changes needed | Requires regular oil checks and changes |

| Cost | Typically higher initial cost | Usually lower initial cost |

| Noise Level | Generally quieter operation | Can be noisier due to oil presence |

| Efficiency | May be less efficient at high pressures | Often more efficient for certain applications |

| Lifespan | Longer lifespan due to reduced wear | Shorter lifespan due to oil degradation |

| Temperature Range | Suitable for a wide range of temperatures | May be sensitive to high-temperature environments |

| Applications | Ideal for food, pharmaceutical, and glass industries | Suitable for general industrial uses and workshops |

| Environmental Impact | Lower environmental impact due to lack of oil | Higher environmental impact due to oil use |

Application of Oil Free Compressor

Food and Beverage Processing

Oil-free compressors are essential for supplying clean air in food and beverage processing facilities, preventing contamination and ensuring product quality

Pharmaceutical Manufacturing

In the pharmaceutical industry, oil-free compressors provide clean air for drug manufacturing, packaging, and testing, maintaining the integrity of pharmaceutical products

Glass Blowing Bottle Industry

Air Supply for Molding: Oil-free compressors provide clean air necessary for shaping molten glass, preventing contamination that could affect the quality of the glass.

Cooling Systems: Used to power cooling systems, maintaining optimal temperatures during the production process to ensure glass integrity.

Medical and Dental Applications

Oil-free compressors power various medical and dental equipment, such as dental drills, respiratory therapy devices, and surgical instruments, ensuring patient safety and well-being

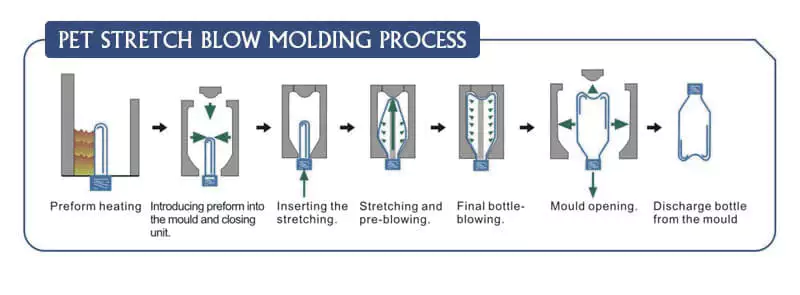

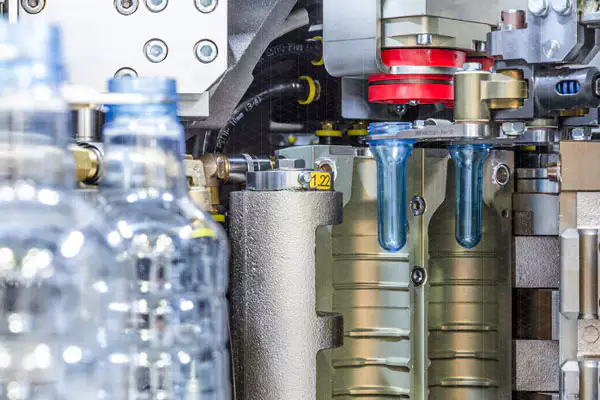

PET Blowing Bottle Industry

Preform Injection: Oil-free compressors are essential for supplying air during the injection molding of PET preforms, ensuring a pure process free from oil contamination.

Blowing Process: High-pressure air is needed for the blowing process to shape the bottles; oil-free compressors provide this while maintaining product quality.

Painting and Spraying

Oil-free compressors deliver clean, dry air to paint guns, preventing the formation of oil droplets in the paint or coating and ensuring a smooth, high-quality finish

How To Maintain Oil Free Compressor?

Here’s a comprehensive guide on how to maintain your oil-free compressor:

Visual Inspection: Perform a daily visual inspection of the compressor for any signs of damage, leaks, or loose components. Check for any abnormal noises or vibrations.

Condensate Drain: Drain the condensate tank daily to prevent moisture buildup and potential damage to the compressor’s internal components.

Air Filter Cleaning: Clean the air intake filter regularly to ensure proper airflow and prevent dust and debris from entering the compressor system. The frequency of cleaning depends on the operating environment and dust levels.

External Cleaning: Keep the compressor clean and free from dust and debris. Wipe down the exterior surfaces with a clean cloth to maintain its appearance and prevent corrosion.

Oil Free Compressor Advantage

Cleaner Air

Oil-free compressors eliminate the risk of oil contamination in the compressed air, ensuring that the delivered air is free from oil particles, contaminants, and odors

Reduced Maintenance

Unlike oil-lubricated compressors that require regular oil changes and filter replacements, oil-free compressors are virtually maintenance-free

Environmentally Friendly

Oil-free compressors eliminate the risk of oil leaks and spills, minimizing their environmental impact

Longer Lifespan

The advanced lubrication technologies used in oil-free compressors, such as Teflon® coatings, graphite seals, and ceramic pistons, contribute to their extended lifespan compared to oil-lubricated models

Gentle Handling

Oil-free compressors are known for their gentle handling of materials. This is particularly important for delicate products, such as electronics components or pharmaceutical ingredients, as it prevents damage or contamination.

Reduced Energy Consumption

Oil-free compressors generally operate with higher efficiency compared to oil-lubricated models. This translates to lower energy consumption and reduced operating costs.

Custom Design

As a service to our customers, we offer extensive manufacturing experience and talent to meet the special needs of custom parts. Our in-house engineering team has extensive experience in designing and custom engineering solutions to meet your requirements. If you don’t see what you’re looking for in our standard range, please inquire about custom options.

Types of Oil Free Compressors

Oil-free compressors are available in various configurations and designs to suit different applications. Some common types include:

-

Piston Compressors: Piston compressors are the most common type of oil-free compressor. They utilize a piston and cylinder mechanism to compress air. Piston compressors are available in various sizes and capacities, making them suitable for a wide range of applications.

-

Rotary Compressors: Rotary compressors use rotating components, such as screw rotors or vanes, to compress air. They offer quieter operation and higher efficiency compared to piston compressors. Rotary compressors are often used in larger industrial applications.

-

Centrifugal Compressors: Centrifugal compressors employ high-speed impellers to accelerate and compress air. They are ideal for high-volume airflows and are commonly used in large industrial settings.

Pel Stretch Blow Molding Process

Preform preparation

PET particles are initially heated and molded into what is known as preforms. These preforms feature a bottleneck shape, while the remainder of the structure is cylindrical.

Heating

The preform is heated using an infrared high-temperature lamp to achieve the optimal temperature and plasticity required for the blow molding process.

Blow molding

The preform is placed into the mold, where the air compressor starts its operation. High-pressure, oil-free compressed air is then injected into the preform, expanding it to fit the mold and forming the final bottle shape.

Cooling & solidification

The bottle is cooled and solidified within the mold to achieve a stable form. To prevent deformation of the bottle neck, it is typically not heated during the blow molding process, and a cooling system is used to keep it at a low temperature.

Demolding & processing

After cooling is completed, the bottle is removed from the mold and may require further processing, such as cleaning, inspection, printing, or labeling.

Industrial oil-free air compressors for sale

Industrial oil-free air compressors are essential in various sectors, including manufacturing, pharmaceuticals, food processing, and electronics. These compressors provide a reliable source of clean, dry air, which is crucial for applications where oil contamination could compromise product quality or safety. Unlike traditional compressors that rely on oil lubrication, oil-free models use advanced materials and designs to minimize friction and wear, resulting in a maintenance-friendly solution.

One significant advantage of oil-free air compressors is their ability to deliver high-quality air without the risk of oil carryover. This characteristic is particularly important in industries like food and beverage, where air quality standards are stringent. For instance, in a food processing plant, using an oil-free compressor can help ensure that compressed air does not contaminate food products, thereby safeguarding consumer health.

Another notable feature is energy efficiency. Many modern industrial oil-free compressors are designed with variable speed drives (VSD), which adjust motor speed based on air demand. This adaptability not only reduces energy consumption but also extends the lifespan of the compressor by minimizing wear and tear. Additionally, oil-free compressors typically have a lower total cost of ownership (TCO) due to reduced maintenance requirements and the absence of oil-related expenses.

When considering purchasing an industrial oil-free air compressor, it’s vital to evaluate factors such as flow rate, pressure rating, and noise levels. For example, a compressor with a high flow rate is essential for operations that require a substantial amount of air, such as pneumatic tools and spray painting.

Energy-efficient oil-free air compressor

Energy-efficient oil-free air compressors are revolutionizing the way industries utilize compressed air, offering both performance and sustainability. These compressors operate without the need for oil lubrication, significantly reducing energy consumption and operational costs. By employing advanced technologies such as variable speed drives (VSD), these compressors can adjust their output according to demand, minimizing energy waste during low usage periods.

The design of energy-efficient oil-free compressors often incorporates lightweight, high-strength materials that enhance performance while reducing overall weight. This innovative engineering allows for higher pressure levels and improved airflow efficiency, resulting in lower energy costs. Moreover, their compact footprint enables installation in space-constrained environments, further optimizing facility layouts.

In applications where air purity is paramount—such as pharmaceuticals, food processing, and electronics—oil-free compressors provide clean, contaminant-free air, eliminating the risk of oil carryover. This not only ensures compliance with stringent industry regulations but also enhances product quality.

Investing in an energy-efficient oil-free air compressor can yield significant long-term savings. The reduced maintenance requirements associated with these systems lead to lower downtime and increased productivity. As industries continue to prioritize sustainability, the demand for energy-efficient oil-free air compressors is likely to grow, making them a critical component in modern manufacturing and processing environments.

Oil-free compressor maintenance tips

Maintaining an oil-free compressor is essential to ensure optimal performance and longevity. Unlike traditional compressors that require oil changes, oil-free models depend on precise engineering and material selection, which necessitates specific maintenance practices.

1. Regular Inspection: Routine checks are crucial. Inspect the air intake filters regularly for dirt and blockages, as clean filters are essential for efficient airflow and performance. A clogged filter can lead to increased energy consumption and strain the compressor.

2. Monitor Pressure Levels: Ensure that the pressure settings are within the manufacturer’s specifications. Operating outside of these parameters can cause excessive wear on components and lead to premature failure.

3. Condensate Management: Oil-free compressors generate condensate, which can accumulate in the tank. Regularly drain the moisture separator to prevent corrosion and maintain air quality. This practice not only enhances performance but also extends the life of the compressor.

4. Check Electrical Components: Periodically inspect electrical connections and control panels for any signs of wear or damage. Faulty electrical components can lead to operational issues, affecting the overall efficiency of the compressor.

5. Clean and Maintain Cooling Systems: Ensure that cooling fins and fans are free from debris. Overheating can lead to significant operational issues, so keeping these areas clean is vital for maintaining optimal temperatures.

6. Follow Manufacturer Guidelines: Always adhere to the maintenance schedule provided by the manufacturer. This includes replacing any consumables, such as desiccant filters, as recommended.

By implementing these maintenance tips, operators can ensure their oil-free compressors remain efficient, reliable, and ready to meet the demands of their specific applications, ultimately enhancing productivity and reducing costs.

Blog

WHY CHOOSE US?

We are one of the best oil free compressor manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!